Kushishino lwegranulation, nokuba ngumatshini wepellet wokufa okanye umatshini wepellet wokufa weringi, umgaqo wayo wokusebenza kukuthembela kwintshukumo ehambelanayo phakathi kweqokobhe elinoxinzelelo kunye nokungunda ukubamba izinto kwaye ungene kwisikhululo esisebenzayo, usikhuphele ngaphakathi. imilo, uze uyinqumle ibe ngamaqhekeza obude obufunekayo nge-blade yokusika.

Iqokobhe lokucofa i-roller

Iqokobhe le-roller yoxinzelelo ikakhulu libandakanya i-eccentric shaft, iibheringi eziqengqelekayo, iqokobhe le-roller yoxinzelelo elinemikhono ngaphandle kwe-shaft yoxinzelelo, kunye nezinto ezisetyenziselwa ukuxhasa kunye nokulungisa iqokobhe le-roller yoxinzelelo.

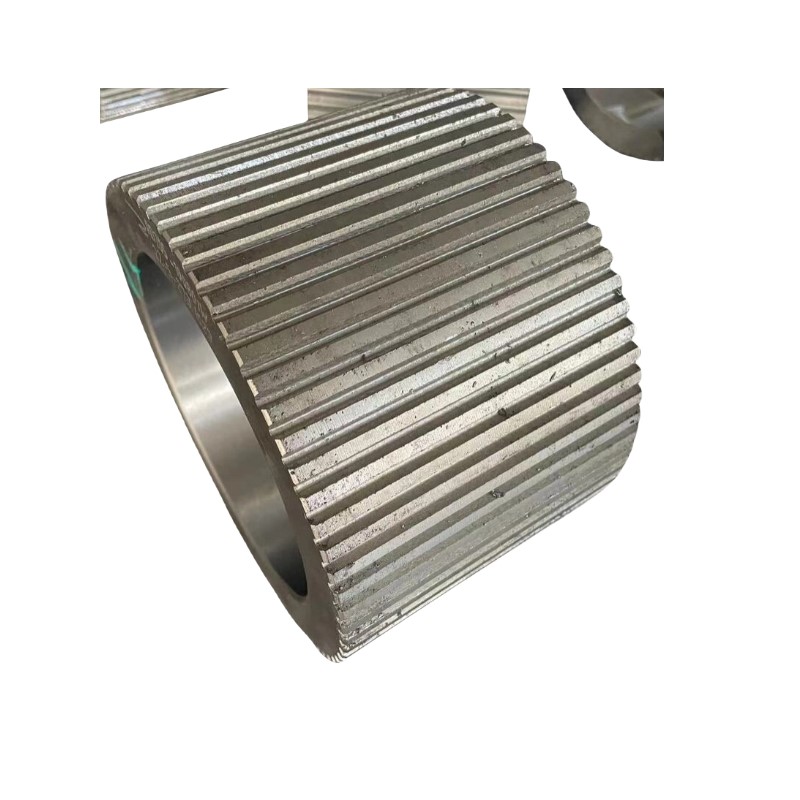

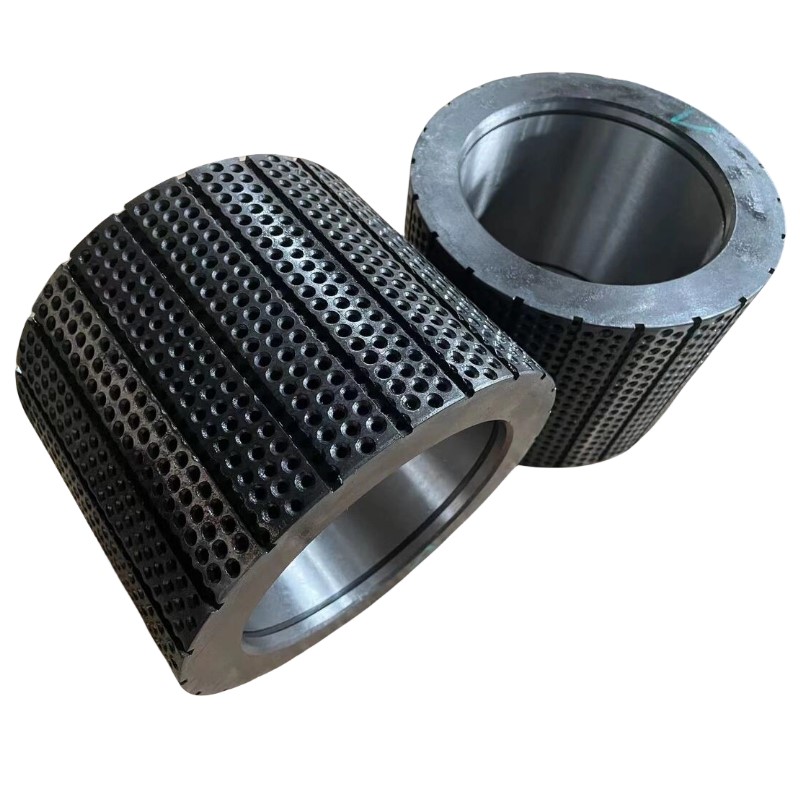

I-rollershell yoxinzelelo icinezela izinto eziphathekayo kwi-mold hole kwaye iyenze phantsi koxinzelelo kwi-mold hole.Ukuze uthintele i-roller yoxinzelelo ukuba ingatyibiliki kwaye inyuse amandla okubamba, kufuneka kubekho amandla athile okubetha phakathi kwe-roller yoxinzelelo kunye nezinto eziphathekayo.Ngoko ke, amanyathelo okunyusa ukungqubuzana kunye nokuxhatshazwa kokugqoka ahlala ethathwa phezu komgangatho we-roller yoxinzelelo.Xa iiparamitha zesakhiwo se-roller yoxinzelelo kunye nesikhunta sinqunywe, ifom yesakhiwo kunye nobukhulu bendawo yangaphandle ye-roller yoxinzelelo inefuthe elibalulekileyo ekusebenzeni kwe-granulation kunye nomgangatho we-particle.

Isakhiwo sobuso beqokobhe le-roller yoxinzelelo

Kukho iintlobo ezintathu eziqhelekileyo zomphezulu we-particle ekhoyo ye-press rollers: i-grooved roller surface, i-grooved roller surface kunye nokutywinwa komphetho, kunye ne-honeycomb roller surface.

I-roller yoxinzelelo lohlobo lwe-toothed groove inomsebenzi olungileyo wokuqengqeleka kwaye isetyenziswa kakhulu kwimizi-mveliso yemfuyo kunye neenkukhu.Nangona kunjalo, ngenxa yokutyibilika kokutya kwi-groove enamazinyo, ukunxiba kwe-roller yoxinzelelo kunye ne-ring mold akufani kakhulu, kwaye ukunxiba kuzo zombini iziphelo ze-roller yoxinzelelo kunye ne-ring mold kunzima kakhulu.

I-toothed groove uhlobo loxinzelelo lwe-roller kunye nokutywinwa komphetho lufanelekile ngokukodwa ukuveliswa kwezinto zasemanzini.Izinto zasemanzini zithandwa kakhulu kwi-sliding ngexesha le-extrusion.Ngenxa yokutywinwa komphetho kumacala omabini egroove enamazinyo, akukho lula ukutyibilika ukuya kumacala omabini ngexesha lokutya, okukhokelela kulwabiwo olufanayo lokutya.Ukunxiba kwe-roller yoxinzelelo kunye ne-ring mold nayo ifana kakhulu, okubangelwa ubude obuhambelanayo beepellets eziveliswayo.

Inzuzo ye-honeycomb roller kukuba ukunxiba kwe-mold ring kufana, kwaye ubude beengqungquthela eziveliswayo nazo zihambelana.Nangona kunjalo, ukusebenza kwekhoyili kubi, okuchaphazela imveliso yegranulator kwaye ayiqhelekanga njengokusetyenziswa kohlobo lwe-slot kwimveliso yangempela.

Oku kulandelayo sisishwankathelo se-10 yeentlobo ze-particle machine pressure rollers ze-Baoshell pressure roller ring molds, kwaye ezi-3 zokugqibela ngokuqinisekileyo zezo ongakhange uzibone!

NO.10 uhlobo lweGroove

NO.9 Uhlobo lwegroove evaliweyo

NO.8 uhlobo lobusi

NO.7 Idayimani imile

NO.6 Igroove edibeneyo

NO.5 Groove+honeycomb

NO.4 I-groove evaliweyo+inqatha lobusi

NO.3 I-groove edibeneyo+inqatha lobusi

NO.2 Ithambo lentlanzi liyaqhuma

NO.1 ripple emile Arc

IMODELI YESEPPECIAL: TUNGSTEN CARBIDE COLLER SHELL

Indlela yonyango yokutyibilika kwe-roller yoxinzelelo lwe-particle machine

Ngenxa yendawo yokusebenza enzima, ubuninzi bokusebenza okuphezulu, kunye nesantya sokugqoka ngokukhawuleza kwegobolondo ye-roller yoxinzelelo, i-roller yoxinzelelo yinxalenye esengozini yomatshini we-particle kwaye kufuneka itshintshwe rhoqo.Umsebenzi wokuvelisa ubonise ukuba ngokude nje iimpawu zezixhobo zokuvelisa zitshintsha okanye ezinye iimeko ziguquka ngexesha lokucubungula, i-phenomenon of slipping of the pressure roller of the particle machine ingenzeka.Ukuba kukho ukutyibilika kwe-roller yoxinzelelo ngexesha lenkqubo ye-granulation, nceda ungothuki.Ngeenkcukacha ezithile, nceda ujonge ezi ndlela zilandelayo:

Isizathu 1: Ukugxila okungalunganga kwe-roller yoxinzelelo kunye nofakelo lwe-spindle

Isisombululo:

Khangela ukuba ukufakwa kweebheringi ze-roller yoxinzelelo kunengqiqo ukuphepha ukubangela ukuba iqokobhe le-roller yoxinzelelo liphambuke kwelinye icala.

Isizathu 2: Umlomo wentsimbi we-ring mold uphantsi, ubangela ukuba umngundo ungatyi izinto

Isisombululo:

Jonga ukuguga kweeclamps, amavili othumelo, kunye nezangqa ze-lining zegranulator.

Lungisa ubunzulu bofakelo lokungunda kweringi, ngempazamo engagqithiyo kwi-0.3mm.

Umsantsa phakathi kweerola zoxinzelelo kufuneka ulungelelaniswe: isiqingatha sendawo yokusebenza ye-roller yoxinzelelo sisebenza kunye nesikhunta, kunye nevili lohlengahlengiso lwe-gap kunye nesijija sokutshixa kufuneka kuqinisekiswe ukuba sikwimeko entle yokusebenza.

Xa i-roller yoxinzelelo iphosa, musa ukuvumela umatshini we-particle ungasebenzi ixesha elide kwaye ulinde ukuba ukhuphe izinto ngokwazo.

Umlinganiselo wokunyanzeliswa kwe-aperture ye-mold aperture esetyenzisiweyo iphezulu kakhulu, nto leyo ebangela ukuchaswa kwezinto eziphezulu zokukhutshwa kwesikhunta kwaye sesinye sezizathu zokutyibilika kwe-roller yoxinzelelo.

Umatshini we-pellet akufanele uvunyelwe ukuba ungasebenzi ngokungeyomfuneko ngaphandle kokutyisa izinto eziphathekayo.

Isizathu sesi-3: Uxinzelelo lwe-roller bearing lubambekile

Isisombululo:

Faka esikhundleni iibheringi zoxinzelelo.

Isizathu 4: Igobolondo le-roller yoxinzelelo ayijikelezi

Isisombululo:

Umgangatho we-roller shell awufanelekanga, utshintshe okanye ulungise i-shell roller.

Xa i-roller yoxinzelelo i-slip, kufuneka imiswe ngexesha elifanelekileyo ukuze ugweme ukungqubuzana okungapheliyo kwe-roller yoxinzelelo.

Isizathu sesi-5: Ukugoba okanye ukukhulula i-spindle ye-roller yoxinzelelo

Isisombululo:

Faka esikhundleni okanye uqinise i-spindle, kwaye ujonge imeko ye-spindle ye-pressure roller xa utshintsha i-ring mold kunye ne-pressure roller.

Isizathu sesi-6: Indawo yokusebenza ye-roller yoxinzelelo ayihambelani ngokufanelekileyo kunye nomgangatho osebenzayo we-ring mold (i-edge crossing)

Isisombululo:

Khangela ukuba i-roller yoxinzelelo ifakwe ngokungafanelekanga kwaye uyitshintshe.

Khangela ukuba i-eccentric shaft ye-roller yoxinzelelo ikhubazekile.

Khangela ukunxiba kwiibheringi eziphambili ze-shaft okanye i-bushings yomatshini wamasuntswana.

Isizathu sesi-7: I-spindle clearance yegranulator inkulu kakhulu

Isisombululo:

Jonga ukuqiniswa kwe-granulator.

Isizathu 8: Izinga lokubethelwa komngundo weringi liphantsi (ngaphantsi kwama-98%)

Isisombululo:

Sebenzisa i-pistol drill ukugqobhoza umngxuma wokungunda, okanye ubilise ngeoyile, uyigaye phambi kokutyisa.

Isizathu 9: Imathiriyeli ekrwada irhabaxa kakhulu kwaye inomthamo ophezulu wokufuma

Isisombululo:

Nika ingqalelo ekugcineni isiqulatho sokufuma esimalunga ne-15%.Ukuba ubumanzi bemathiriyeli ekrwada buphezulu kakhulu, kuya kubakho ukuvaleka kokungunda kunye nokutyibilika emva kokuba imathiriyeli ekrwada ingene kumngundo weringi.Uluhlu lokulawula ukufuma kwezinto eziluhlaza luphakathi kwe-13-20%.

Isizathu se-10: Ukutya kokungunda okutsha ngokukhawuleza

Isisombululo:

Lungisa isantya ukuze uqinisekise ukuba i-roller yoxinzelelo ine-traction eyaneleyo, thintela i-roller yoxinzelelo ukuba ikhuphe, kwaye ukhangele ngokukhawuleza ukunxiba kwe-ring mold kunye ne-pressure roller.

Ixesha lokuposa: Mar-25-2024