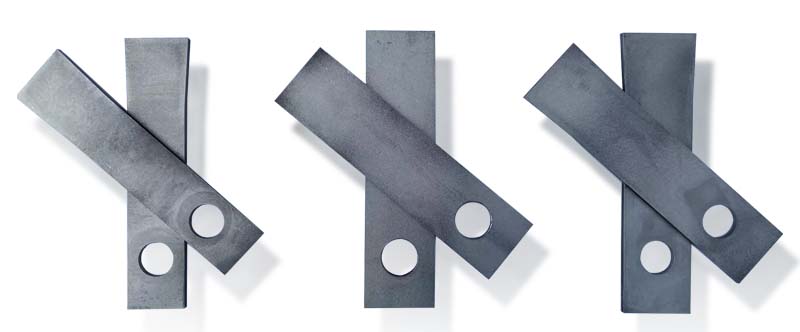

Zininzi iimilo ze-Smooth Plate Hammer Blade esetyenziswayo ngoku, kodwa eyona isetyenziswa kakhulu yipleyiti emile okwesando soxande, ngenxa yokumila kwayo kulula, ukwenziwa lula, kunye nokuguquguquka okuhle.

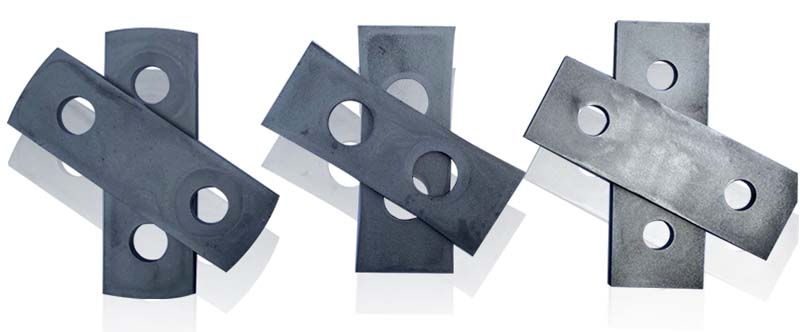

I-Smooth Plate Hammer Blade ine-pin shafts ezimbini, enye yazo ifakwe kwi-pin shaft, kwaye iikona ezine zingasetyenziselwa umsebenzi.Ukuwelda, ukuwelda i-tungsten carbide okanye ukuwelda ialloyi ekhethekileyo ekwazi ukumelana nokunxitywa kwicala lokusebenza ukwandisa ubomi benkonzo, kodwa iindleko zokwenziwa ziphezulu.Ukunganyangeki kakuhle kwe-abrasion.I-hammer ye-annular inomngxuma omnye wepini, kwaye i-angle yokusebenza iguqulwa ngokuzenzekelayo ngexesha lomsebenzi, ngoko ukugqoka kufana kwaye ubomi benkonzo bude, kodwa isakhiwo sinzima.Ihamile yentsimbi edibeneyo yoxande yintsimbi yentsimbi enobunzima obuphezulu kwiindawo ezimbini kunye nokuqina okulungileyo kwi-interlayer enikezelwa yi-rolling Mill.Kulula ukuyenza kwaye iphantsi kweendleko.

Iimvavanyo zibonise ukuba ubude obufanelekileyo be-Smooth Plate Hammer Blade bunceda ekunyuseni imveliso ye-kWh, kodwa ukuba ide kakhulu, ukusetyenziswa kwesinyithi kuya kwanda kwaye i-kWh iya kuncipha.Ngokutsho kweChina Agricultural Mechanisation Research Institute isebenzisa i-1.6mm, 3.0mm, 5.0mm, 6.25mm iihamile zokungqimba ezine zovavanyo lokutyumza umbona, kuqukunjelwa ukuba isiphumo sokutyunyuzwa kwe-1.6mm ngama-45% ngaphezulu kwesando se-6.25mm, kwaye I-25.4% ngaphezulu kwe-5mm.Ukusebenza kakuhle kokutyumza ngesando esincinci siphezulu, kodwa ubomi benkonzo bufutshane.Ubunzima besando esisetyenzisiweyo kufuneka buhluke ngokuxhomekeke kwinto etyumkileyo kunye nobukhulu bemodeli.

Ixesha lokuposa: Jan-04-2023