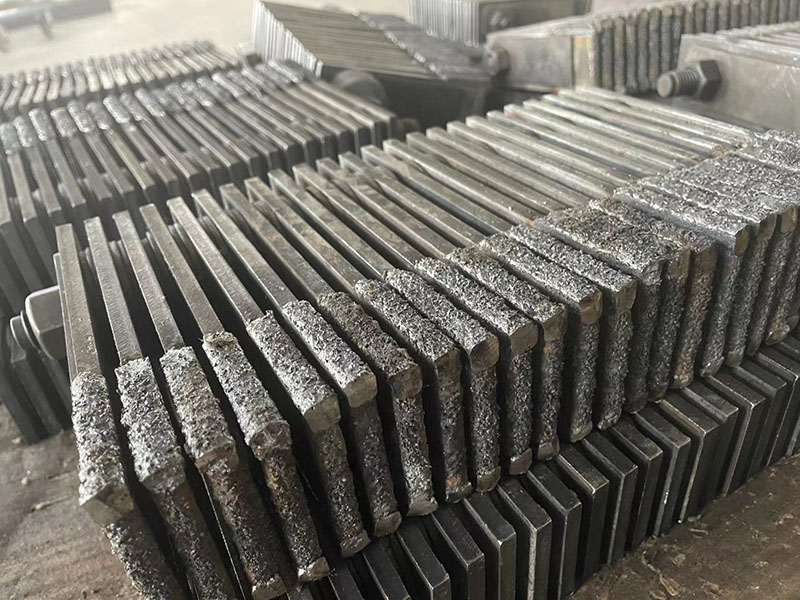

I-Tungsten Carbide i-Welding ye-Welding Hammer Blade

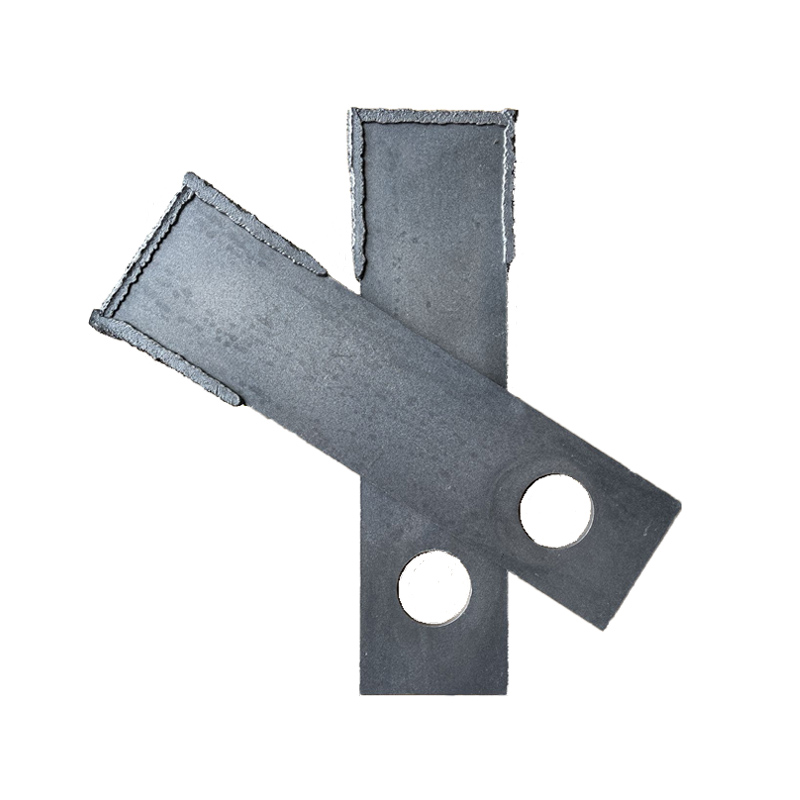

1. Ubume:Intloko enye uhlobo lomngxuma, elinentloko kabini uhlobo lomngxuma

2. Ubungakanani:Ubukhulu obahlukeneyo, obulungiselelweyo

3. Izinto:Umgangatho ophezulu wentsimbi ekwaziyo ukunxiba, intambo yokuwelda enganxitywayo, amasuntswana e-tungsten carbide

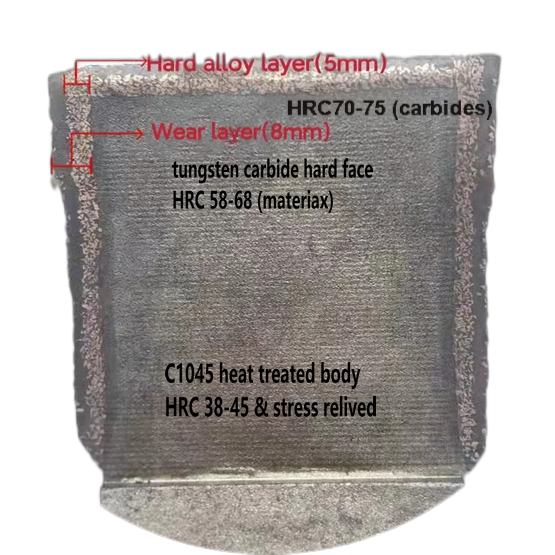

4. Ukuqina:

I-HRC70-75 (i-tungsten carbide layer)

I-hardface ye-welding eyongeziweyo-i-HRC 55-63 (i-wear-resistant layer)

Umzimba weHammer - HRC 38-45 kunye noNcedo lweStress

Ukujikeleza umngxuma: HRC38-45 (ubunzima bunokwenziwa ngokweemfuno zabathengi)

5. Umaleko omnye we-hammer blade:Ukuphakama kwe-tungsten carbide layer ifikelela kwi-3mm-4mm.

Ubude obupheleleyo bokumelana nokunxiba bufikelela kwi-6mm-8mm. Ubomi bayo benkonzo buphindwe kabini kwiimveliso ezifanayo. Inokunciphisa iindleko zokutyumza malunga ne-50% kwaye igcine ixesha lokubuyisela.

6. Umaleko ophindwe kabini we-hammer blade:Ukuphakama kwe-tungsten carbide layer ifikelela kwi-6mm-8mm, kwaye ukuphakama kokumelana nokunxiba kufikelela kwi-10mm-12mm, enenzuzo engenakulinganiswa.

1. Ukuphakama kwe-weld overlay layer ifikelela kwi-3mm-4mm, kwaye ukuphakama kokumelana nokunxiba kufikelela kwi-6mm-8mm. Ukuphakama kokumelana nokunxiba kwezinye iimveliso ezifanayo kwimarike yi-3mm-4mm kuphela.

2. Kukho inani elikhulu lee-tungsten carbide particles in the welding layer, okwenza imveliso ingagugi. Akukho zincinci ze-tungsten carbide kwezinye iimveliso ezifanayo kwimarike.

HMT'ihammer blade

Imakethi' isando blade

1. Ukuqina okuphezulu kunye nokumelana nokunxiba:Ihamile ye-tungsten carbide inobulukhuni obuphezulu kakhulu kwaye inokugcina ubulukhuni bomphezulu ixesha elide kwindawo yokungqubana kunye nokunxiba, ngaloo ndlela yandisa ubomi benkonzo yezixhobo, ukunciphisa ixesha lokuphumla kunye neendleko zokuyigcina.

2. Ukumelana nokuMhlwa:Iihamile ze-tungsten carbide zisebenza kakuhle kwiindawo ezinobungozi ezifana nokufuma, i-asidi, kunye ne-alkali, kwaye zingasetyenziselwa ixesha elide kwezi ndawo ngaphandle kokugqwala okanye ukonakala. Zifanele izixhobo kunye namacandelo ezakhiwo kwimimandla efana nolwandle, unyango lwamanzi, kunye nobunjineli bemichiza.

3. Ukumelana nobushushu obuphezulu:I-Tungsten carbide inokugcina ukusebenza okuzinzileyo kwiindawo eziphakamileyo zokushisa ngaphandle kokuthambisa okanye ukunyibilika. Oku kwenza ukuba idlale indima ebalulekileyo kwizicelo zobushushu obuphezulu ezifana nemigodi, isinyithi, kunye nepetroleum.

4. Ukuchasa impembelelo:Izando ze-tungsten carbide zinokuqina okulungileyo kunye nokuchasana kweempembelelo, ezifanelekileyo kwizixhobo kunye namacandelo esakhiwo phantsi komthwalo ophezulu kunye neemeko zomthwalo wempembelelo, ezifana nezixhobo zoomatshini, izithuthi, kunye nezithuthi zokuthutha kwimigodi kunye namashishini okwakha.

Sinokubonelela ngesando esikhethekileyo se-tungsten carbide. Ubomi benkonzo buphindwe kabini kunezinye iimveliso ezifanayo, ezinokunciphisa iindleko zokutyumza malunga ne-50% -60% kunye nokugcina ixesha lokutshintsha i-hammer blades.

I-tungsten carbide hammer blade, Tungsten carbide hardness HRC70-75, hard surface hardness HRC55-63 (ukunxiba-resistant umaleko) ukwenzela ukuwelda ukwaleka. Emva kokusila, Ayigcini nje kuphela ubukhali be-hammer blade cut, kodwa iphinda ikhulise ukunyanzeliswa kwe-hammer blade.

1. Uhlobo oluqhelekileyo- i-welded kwelinye icala, ixabiso eliphantsi

2. Uhlobo oluneentloko ezimbini- isetyenziswe kabini, ukonga iindleko zokusetyenziswa

3. Uhlobo olwandisiweyo lwecala- ubude boluhlu lwe-welding kumacala omabini lwandisiwe ukuya kwi-90MM

4. Uhlobo lokucheba- Emva kokugaya umaleko we-welding, umgca wokusika uqulunqwa, onomsebenzi omhle wokucheba

5. Uhlobo olubhityileyo kakhulu-Unako ukuwelda eyona blade yesando ibhityileyo, enobunzima bomzimba obuyi-3MM kuphela

6. Uhlobo oluphindwe kabini- Itekhnoloji ye-welding ye-two-layer, enokumelana nokunxiba kabini

7. I-tungsten carbide blade ye-sugar cane shredder cutter