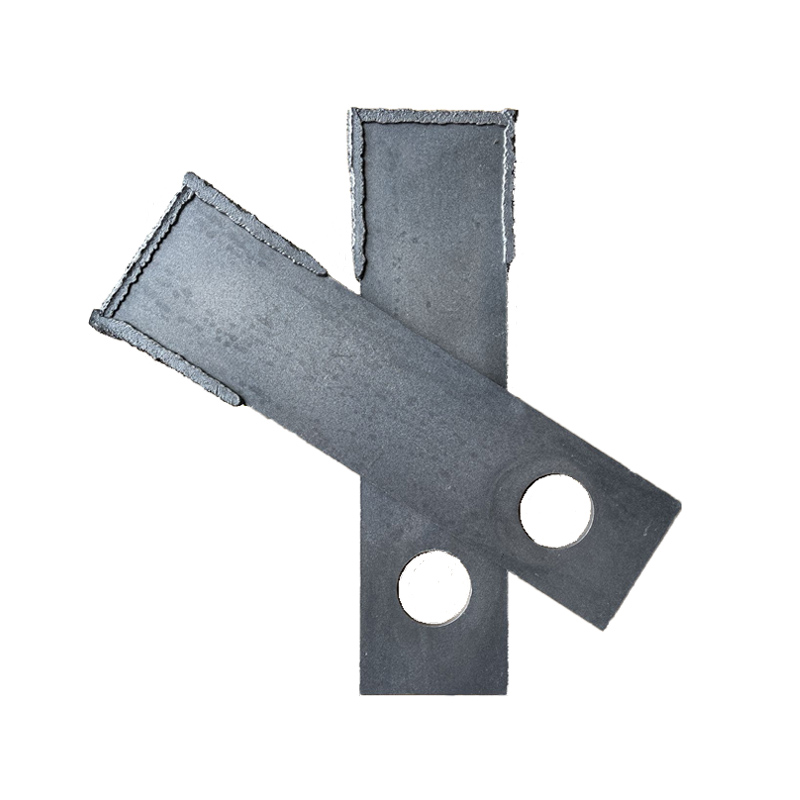

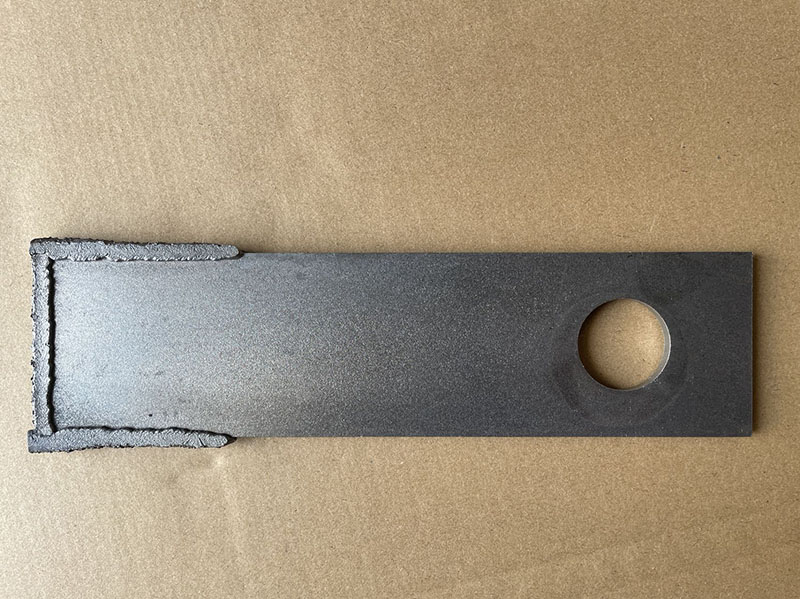

I-Tungsten Carbide Hammer Blade Enomngxuma omnye

Ukuqina komphezulu

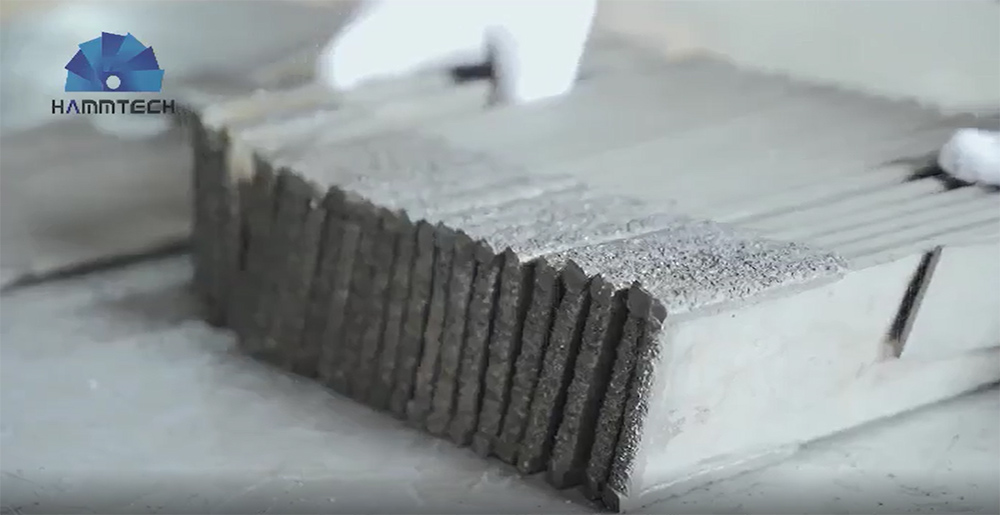

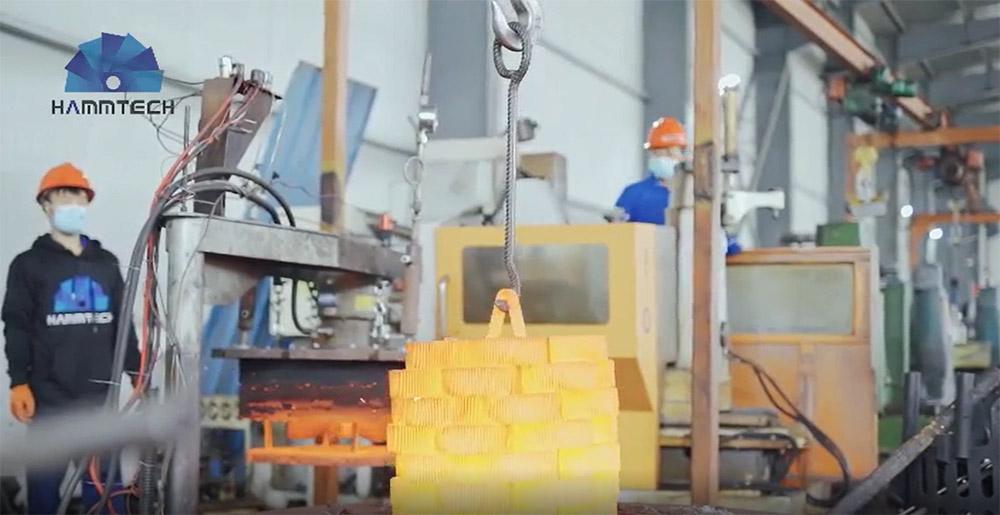

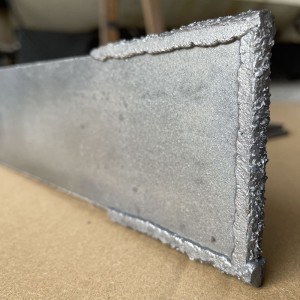

I-tungsten carbide alloy igqitywe kwimida yokusebenza ye-hammer blade, kunye nobukhulu be-1 ukuya kwi-3 mm. Ngokweziphumo zovavanyo, ubomi benkonzo yeencakuba zesando ezishiyileyo ze-tungsten carbide alloy alloy yi-7 ~ 8 ngokuphindwe kabini kunobo be-65Mn yeencakuba zesando ezicinyiweyo zizonke, kodwa ixabiso lokwenziwa kwesando sangaphambili lingaphezulu ngokuphindwe kabini ukuphakama.

Ukuchaneka koMatshini

Isando siyinxalenye yesantya esiphezulu, kwaye ukuchaneka kwayo kokuvelisa kunempembelelo enkulu kwibhalansi ye-rotor ye-pulverizer. Ngokuqhelekileyo kufuneka ukuba umehluko omkhulu phakathi kweziphi na amaqela amabini eehamile kwi-rotor akufanele idlule i-5g. Ngoko ke, ukuchaneka kwesando kufuneka kulawulwe ngokungqongqo ngexesha lenkqubo yokucubungula, ngokukodwa kwi-surfacing tungsten carbide hammers, umgangatho wenkqubo yokujonga phezulu kufuneka uqinisekiswe ngokungqongqo. Iintsimbi zesando kufuneka zifakwe kwiiseti, kwaye ukutshintshiselana okungahleliwe phakathi kweesethi akuvumelekanga.

Ubungakanani kunye noLungiselelo

Inani kunye nokucwangciswa kweentsimbi zesando kwi-rotor ye-hammer mill kuchaphazela ibhalansi ye-rotor, ukuhanjiswa kwezinto eziphathekayo kwigumbi lokutyumza, ukufana kwesando sokugqoka, kunye nokusebenza kakuhle kwe-crusher.

Inani lee-hammer blades lilinganiswa nenani leentsimbi zesando kwiyunithi nganye yobubanzi be-rotor (i-hammer density), ubuninzi bukhulu kakhulu ukuba i-rotor iqalise i-torque, izinto zibethelwa amaxesha amaninzi, kwaye imveliso ye-kWh iyancipha; Uxinaniso luncinci kakhulu kwimveliso yesityuli iya kuchaphazeleka.

Ulungelelwaniso lwee-hammer blades lubhekiselele kubudlelwane bendawo ehambelanayo phakathi kwamaqela eentsimbi zehamile kwi-rotor naphakathi kweqela elifanayo leencakuba zehamile. Ukulungelelaniswa kwee-hammer blades kukulungele ukufezekisa ezi mfuno zilandelayo: xa i-rotor ijikeleza, i-trajectory ye-hammer blade ayiphindi; izinto eziphathekayo azitshintshi kwicala elinye kwigumbi lokutyumza phantsi kweentsimbi zesando (ngaphandle kweemfuno ezikhethekileyo); i-rotor ilungelelaniswa ngokwemiqathango yamandla kwaye ayishukumi ngesantya esiphezulu.

Umgaqo wokuSebenza

Iqela leentsimbi zesando lijikeleza ngokuqhutywa kwamandla, kwaye emva kokufikelela kwisantya esithile, izinto ezifakwe kumatshini ziya kutyunyuzwa (ezinkulu eziphukileyo ezincinci), kwaye phantsi kwesenzo somqhubi, izinto ezichotshoziweyo ziya kukhutshwa kumatshini ngokusebenzisa imingxuma yesikrini.

Ukutshintshwa kwemveliso

I-hammer blade yinxalenye esebenzayo ye-crusher ebetha ngokuthe ngqo kwizinto eziphathekayo, kwaye ngoko ke yeyona nto ikhawulezayo yokunxiba kwaye ithatha indawo yokunxiba. Xa ii-angles ezine zokusebenza kwee-hammer blades ziphelile, kufuneka zitshintshwe ngexesha.