Ubomi benkonzo yeintsimbi yehamileinxulumene nezinto ze-hammer blade ngokwayo, uhlobo lwezinto ezichotshoziweyo, njl. Iisando zesando kwimarike zahlulwe ngokweendidi ezintathu: iincakuba zehamile eziqhelekileyo, iincakuba zesando ezishiyileyo ze-tungsten carbide, kunye neencakuba zehamile ezidityanisiweyo ze-tungsten carbide.

Phakathi kwabo, okoko nje iqhekeza lehamile eliqhelekileyo sisiqwenga sehamile esiphathwe ngobushushu, okanye kusetyenziswa nje iqhekeza lentsimbi yentsimbi engama-65Mn, ixabiso lolu hlobo lwesando lincinci, kodwa ubomi benkonzo obuhambelanayo bufutshane.

Izando zokutshiza ze-Tungsten carbide zisetyenziswa ngokubanzi kwimarike, kusetyenziswa itekhnoloji ye-oxyacetylene yokutshiza ukutshiza i-weld tungsten carbide powder kwi-hammer substrate, emva koko ubushushu buphathe isando ukuvelisa imveliso yokugqibela. Nangona kunjalo, ngenxa yemeko enzima yemveliso kunye nefuthe le-tungsten carbide welding wire quality, umgangatho wesando sokugqibela se-tungsten carbide nawo awulingani, uhlala ukhatshwa ziziphene ezifana ne-pores kunye nokufakwa kwi-weld layer, echaphazela kakhulu ubomi bayo benkonzo. Ngokukodwa xa izinto eziqina kancinci zophukile, kulula ukubangela ukuba i-weld iwa. Ukongezelela, inkqubo yokuvelisa ihamba kunye nobuninzi bothuli kunye neegesi ezinobungozi, ezingenakukwazi ukufikelela kwi-automation, kwaye amathemba awathembisi kakhulu.

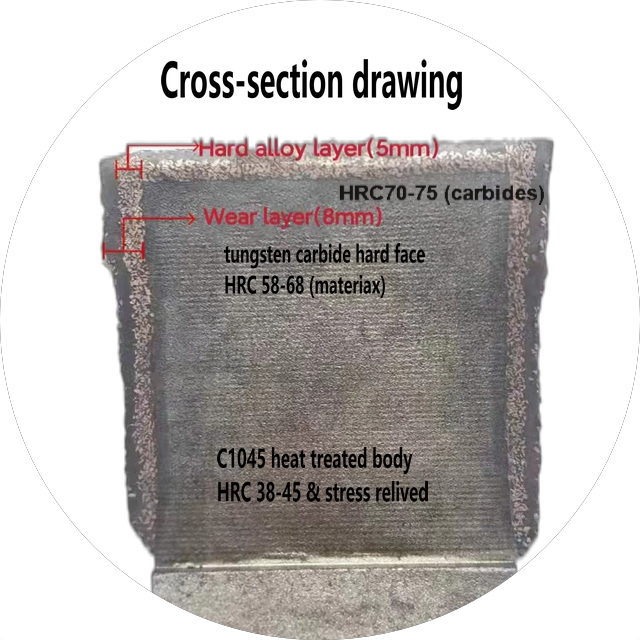

I-HMT ye-tungsten carbide fusion welding ihamile ithatha itekhnoloji ye-plasma welding cladding, ebeka umaleko wamasuntswana e-alloy eqinile kwi-substrate yehamile, ukuphumeza phantse ubukhulu obufanayo phakathi kwesando sesando kunye ne-alloy welding eqinile. Ngelo xesha, i-particle nganye enzima ye-alloy inomda wokusika we-multi-directional, iphucula kakhulu ukusebenza kwe-shear yesando. Iziqwenga zesando ezidityanisiweyo ze-HMT zinomsebenzi ogqwesileyo, zinokumelana okungaphezulu kokunxiba, ubomi benkonzo, ukuxhathisa impembelelo, kunye nokusebenza kakuhle xa kuthelekiswa neziqwenga zesando ezishiyileyo ze-tungsten carbide. Ngaphezu koko, inkqubo yemveliso inokuthi izenzekele kwaye ihambelane nokusingqongileyo, iyenze ibe ngumkhwa kwimveliso yanamhlanje yesando.

Ukutyunyuzwa kwezinto eziphathekayo kunempembelelo ebalulekileyo kubomi benkonzo yeehamile, kwaye ukusebenzisa izando ezahlukeneyo ukutyumza izinto ezahlukeneyo kunokuphucula kakhulu ukusebenza kakuhle. Ezinye izinto zinobunzima obuphezulu, ngoko ke amandla empembelelo kwihamile nawo anamandla kakhulu. Umzekelo, xa i-bamboo feed kunye ne-tungsten carbide spray welding isando saphukile, umaleko we-weld udla ngokuwa. Kwizinto eziphathekayo ezinokunxitywa okubalulekileyo, ubude bomgangatho wokumelana nokunxiba kufuneka bunyuswe nge-100mm, njengokutya kwengqolowa. Kukwakho nodidi lweebhloko zokhuni ezityumkileyo, ezinempembelelo ephezulu kunye nokunxiba, kunye neehamile zokutshiza ze-tungsten carbide azinakusetyenziswa kwaphela. Kwiihamile eziqhelekileyo, ubomi babo benkonzo bufutshane. Ukutyunyuzwa kwezinto ezinjalo, iihamile ze-HMT ze-alloy fusion welding zinokuhlangabezana neemfuno kakuhle kakhulu. Emva kokusetyenziswa ngokubonakalayo ngumvelisi weebhloko zomthi ezityumkileyo, kungqiniwe ukuba iihamile zokuwelda eziqinileyo ze-HMT zinokuhlangabezana neemfuno kakuhle kakhulu. Ukongeza, isiqulatho sokufuma sombona sikwanegalelo elibonakalayo ekusebenzeni kakuhle kokutyumza. Xa umthamo womswakama uphezulu, ukunxiba kwehamile kukhulu kwaye ubomi benkonzo bufutshane.

Ixesha lokuposa: Apr-02-2025