Xa kuthelekiswa nentsimbi yesiko yemanganese okanye intsimbi yesixhobo, izando ze-tungsten carbide zineengenelo ezibalulekileyo ekuxhathiseni ukunxiba kunye nobomi benkonzo. Nangona intsimbi ye-manganese okanye intsimbi yesixhobo inokuxhathisa okuthile, i-tungsten carbide hammer blade inobunzima obuphezulu kunye nokumelana okunamandla okunxiba, ngakumbi xa ujongana nemathiriyeli enzima.

I-Tungsten carbide hammer knife crusher isetyenziswa ngokubanzi ukutyumza okurhabaxa kunye nokuphakathi kwezixhobo ezahlukeneyo ezinamandla acinezelayo angaphantsi kwe-320 megapascals. Inomlinganiselo omkhulu wokutyumza, ukusebenza lula, ukuguquguquka kwiintlobo ezahlukeneyo zezixhobo, kunye namandla aqinileyo okutyumza, kwaye ithatha indawo enkulu kwintsimi yezixhobo zokutyumza. I-Hammer knife crusher ilungele ukutyumza izixhobo ezahlukeneyo kunye neeminerali, kwaye isetyenziswe ngokubanzi kumashishini ahlukeneyo afana ne-electronics, iyeza, i-ceramics, i-silicon ye-polycrystalline, i-aerospace, i-glass optical, iibhetri, iziseko ezintathu ze-fluorescent powder iibhetri, amandla amatsha, i-metallurgy, amalahle, i-ore, imboni yekhemikhali, izinto zokwakha, i-geology, i-gapcharge, i-gap, njl njl. ubungakanani bamasuntswana ukuhlangabezana neemfuno ezahlukeneyo zabasebenzisi abahlukeneyo. Izityumli zeemela zehamile zixhomekeke ikakhulu kwimpembelelo yokutyumza imathiriyeli. Inkqubo yokutyumza ifana ngolu hlobo lulandelayo: izinto eziphathekayo zingena kwi-crusher kwaye zichithwa yimpembelelo yentloko yesando ejikelezayo ejikelezayo. Isixhobo esityumkileyo sifumana amandla e-kinetic kwintloko yehamile kwaye igxalathelana ukuya kwi-baffle kunye ne-sieve bar ngaphakathi kwesakhelo ngesantya esiphezulu. Ngexesha elifanayo, izinto eziphathekayo zingqubuzana kunye kwaye zityunyuzwe ngamaxesha amaninzi. Izinto ezincinci kune-gap phakathi kwemivalo ye-sieve zikhutshwe kwi-gap, kwaye ezinye izinto ezinkulu zichithwa kwakhona ngempembelelo, ukugaya, kunye nokudibanisa kwentloko yesando kwi-bar ye-sieve. Izinto eziphathekayo zikhutshwe kwi-gap ngentloko yesando, ngaloo ndlela ifumana imveliso yobungakanani obufunwayo.

Iimpawu zeMveliso:

1. Ukunxiba okuphantsi kakhulu (PPM) kunokuthintela ukungcoliseka kwezinto.

2. Ubomi benkonzo ende kunye neendleko zokusebenza eziphantsi.

3. Intloko yesando yenziwe nge-tungsten carbide material, engaguqukiyo, i-corrosion-resistant, i-imperial resistant, kunye ne-high-temperature resistant.

4. Xa usebenza, uthuli luncinci, ingxolo iphantsi, kwaye umsebenzi ulungile.

Izando ze-Tungsten carbide zifanelekile ukutyumza izinto ezahlukeneyo, kubandakanywa izinto ezinzima ezifana nommbila, ukutya kwe-soya, i-sorghum, njl. Ukongeza, iziqwenga zesando ze-tungsten carbide zinokumelana ne-asidi, ukuxhathisa kwe-alkali, ukumelana nobushushu obuphantsi, ukumelana nomlilo kunye nezinye iipropathi, ezifanelekileyo kwiindawo ezahlukeneyo zokusebenza eziqatha.

Iimpawu kunye neemeko zeSicelo seTungsten Carbide Hammer beater

Ukuqina okuphezulu: I-tungsten carbide hammer beater inobunzima obuphezulu kakhulu kwaye inokusika kwaye ityumze phantse nayiphi na enye into.

Ukumelana nokunxiba: Ngenxa yokuqina kwayo okuphezulu, i-tungsten carbide hammer mill beater inxiba kancinci kakhulu ngexesha lenkqubo yokutyumza kwaye ifanelekile ukusetyenziswa ixesha elide.

Ukumelana nobushushu obuphezulu: I-Tungsten carbide hammer beater inokumelana nobushushu obuphezulu kwaye inokugcina ukusebenza kwayo ngexesha lokusebenza ngesantya esiphezulu.

Ukusetyenziswa okubanzi: Ifanelekile kwiindawo ezahlukeneyo zokusebenza ezilukhuni, ezifana nokuxhathisa i-asidi, ukuxhathisa kwe-alkali, ukumelana nobushushu obuphantsi, ukuxhathisa umlilo, njl.

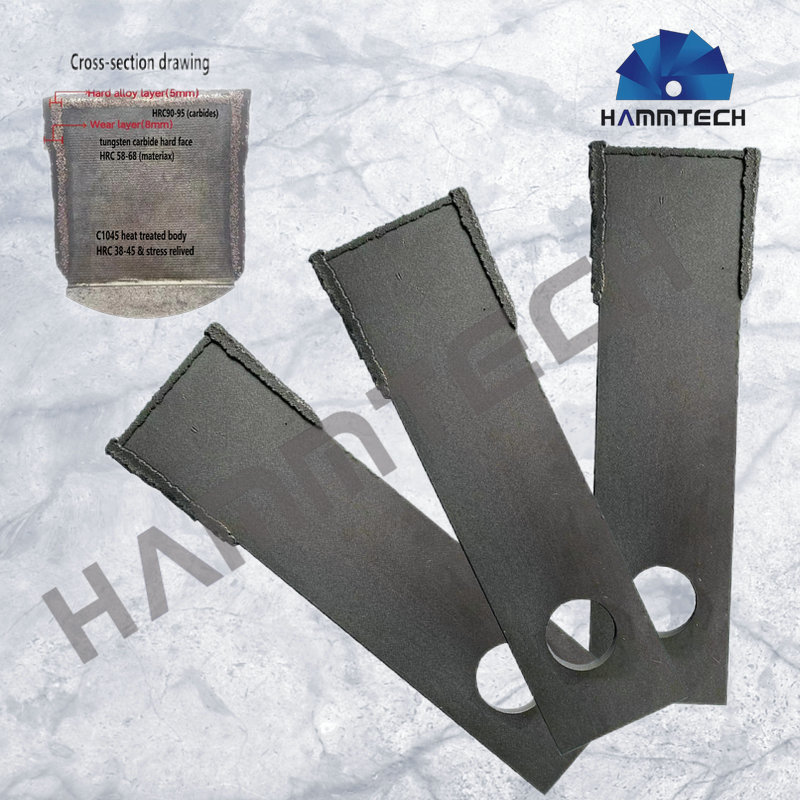

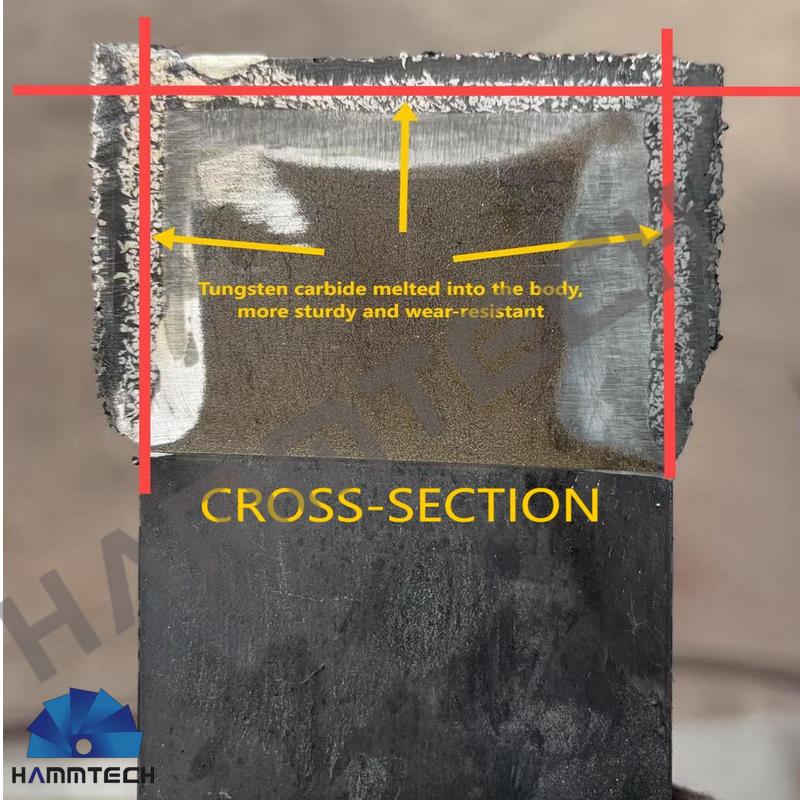

Ubunqabileyo bethu be-tungsten carbide hammer blades;

Samkela itekhnoloji ye-alloy ye-alloy enzima, eyenza i-high-temperature metal melt pool kumphezulu we-workpiece, kwaye ngokufanayo ithumela amasuntswana e-alloy enzima kwi-melt pool. Emva kokupholisa, iincinci ze-alloy eziqinileyo zenza i-alloy layer. Ngenxa yokunyibilika kunye nokuqiniswa komzimba wesinyithi, umaleko ongaguqukiyo wenziwa, kwaye akukho miba efana nokuqhekeka kwe-welding okanye ukucoca.

Ixesha lokuposa: Dec-20-2024